#FWD2022 - Simone Resta Q&A: How to build a car from scratch

September 8, 2021

Following last week’s launch of #FWD2022 – a series of content and updates on the creation of the VF-22 and the group behind a new era of racing for the American F1 team – we reconvene with Simone Resta, Technical Director at Uralkali Haas F1 Team for part two of an exclusive Q&A.

You’ve introduced the names behind Uralkali Haas F1 Team’s future challenger, can you now provide an insight into how to build a Formula 1 car from scratch and how the team is looking forward to 2022…

“Building a Formula 1 car from scratch has been a very big challenge for the new technical group as the project started in parallel with the group’s creation, as well as to all the new processes and reviews we’ve put in place.

“To explain clearly, after receiving the new set of regulations, the group identified the objectives for the new car, then defined the project plan and the required resources. At the concept stage we then investigated development directions aimed to find answers to the above-mentioned points.

“From the concept phase, the project gradually transitions to the engineering phase, involving the project of readying components – their procurement, assembly, indoor testing and FIA homologation before running trackside. Within the legal boundaries defined by the FIA, Uralkali Haas F1 Team has a collaboration with Ferrari, purchasing not only the powertrain but also a series of parts of the TRQ transferable components family.”

You mention indoor testing. What can you tell us about the facilities and our wind tunnel model?

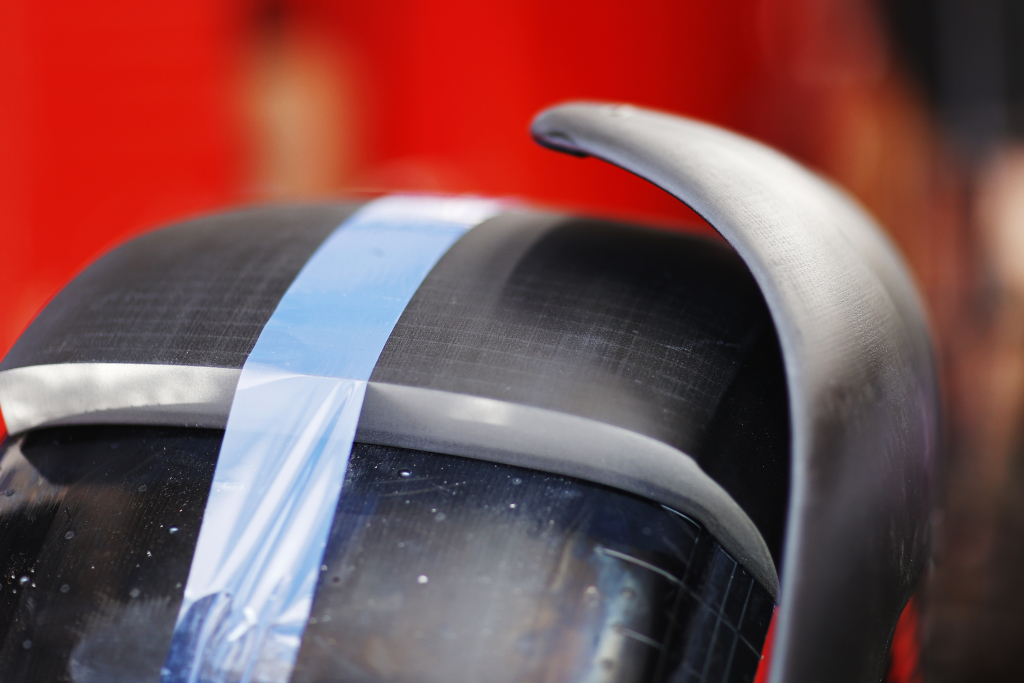

“Since the beginning of our collaboration with Ferrari, we have been using their wind tunnel. The 2022 wind tunnel model has been prepared at the start of the year in order to start as early as possible on the 2022 car development, following final legalization work on the current car.

“The new wind tunnel model, 60% scale as its predecessors, looks quite different if compared to the previous ones due to the combination of several factors.”

Was that the model from the previous car or a brand-new model?

“It is a brand-new model, we started from scratch. The model features new front and rear tire and rim dimensions and a complete review of the bodywork regulations and dimensions.

“This will include a completely new design for front and rear wings, bodywork, floor and diffuser, brakes ducts, wheel fairing and suspension too. The amount of freedom to develop aerodynamic surfaces has been reduced, but still allows teams to develop different geometries and extract performance, and as always, the devil is in the details.

“A very important tool to develop the performance of the car is the CFD, Computational Fluid Dynamics, that allows the team of aerodynamicists to perform virtual simulations before testing the model scale parts into the wind tunnel. The maximum number of CFD runs is specified by the regulations as well as the maximum number of wind tunnel tests.”

What exactly is being worked on in the wind tunnel? It’s obviously aerodynamics, but is it one day the front wing, the next day the rear bodywork? How does the program come together?

“Almost every week we develop the new model in the wind tunnel according to our testing calendar. The team of aerodynamicists, following the agreed development directions and testing plans, prepares the set of components to be tested looking to extract performance.

“Depending on the testing plan, in a normal day we can test a family of front wings, then switch on new chassis geometries, then develop new bodywork shapes, then restart the next day with floors, rear wings, brake ducts etc. – basically everything is in development.

“In simple terms, the development team prepare the new components, follow the test in the wind tunnel and gathers the results, study the data, and make sure the findings will be considered for the next component iteration in the tunnel, and the next iteration can happen the next day, the next week or in a longer time depending on the complexity of the changes.

“A close collaboration between the aero group and the design office is key to maximizing the development efficiency.”

Where is the team right now in the design process?

“The team is in the advanced concept phase. There’s still full freedom to develop each component but we are getting close to the first components geometry freeze.

“I shouldn’t be sharing this, but in the spirit of bringing our fans on the journey with us, one of the first definitions is the fuel cell one. The first information released to the supplier is the fuel cell shape. Once you define that, it means that this part of the chassis is defined. That becomes a constraint, and you keep working on the remaining parts of the car. So that is the first component freeze.

“But of course, it's not a fully sequential job, it’s concurrent engineering. We created specific working groups to manage the project on certain parts of the car. We involve every member of the team, trying to empower them so there are not just two or three superstars in the team. Instead, it’s the person doing the aerodynamic work on the front wing working with the designer of the front wing and the structural engineer and they're all around the table and discussing. Of course, it’s a combination of bottom-up processes together with top-down processes, but overall, we firmly believe in individual engineering empowerment to contribute to the team performance. That’s a key aspect.”

How do you then incorporate into that the physical components?

“Everything runs in parallel, 100 percent, with a concurrent engineering process. The group of aerodynamicists, the designers, the performance engineers, the program managers and all the engineers across the team work simultaneously developing the vehicle components according to the defined plan. The plan features release dates by which certain geometry will have to be frozen, from this point onwards the scope of development is partially reduced transitioning from the concept phase on to the engineering phase.”

When does race engineering come into this process because there’s a group of people designing the product and then there’s the people who are running it…

“The race engineering group is a key asset for each team. It’s the group of engineers that has the duty to run the track program supporting the drivers to extract the full potential from the car and give feedback to the development group at the factory to improve the car performance. The race engineering members are kept updated about the 2022 project evolution whilst running the 2021 car trackside. At the end of this year, once the 2021 car is pensioned, it will be the time for the race engineers to adopt our new baby, the 2022 car. This will involve studying all the data needed to prepare the new car assembly, indoor preparation and testing activities and finally the trackside launch.”

By not developing the current car and looking forward to 2022, what can fans expect from the VF-22 and what are the realistic aims for the team next year?

“You have kept the most difficult question at the end! As a team, we have decided to stop the development of the 2021 car at the beginning of the year, trying to focus most of our energies on to the 2022 car.

“We started a bit on the back-foot as we needed to complete the structure while developing processes and tools as well, but we believe that this investment will pay off and we’ll have a competitive car, and we’ll have lots of fun again in 2022.”