Haas’ family moved to Los Angeles when he was still a child, where his father worked as a designer of electrical cabinets for Hughes Aircraft and his mother was a schoolteacher. The second oldest of four children, Haas’ family instilled at an early age the importance of hard work and responsibility. He delivered newspapers while in elementary school and at age 14 began working in a machine shop where he swept floors and kept the facility clean. After only six months, Haas was setting up lathes and conventional milling machines. He continued to work at machine shops through high school and college, mastering the machining techniques that would lead him to found Haas Automation in 1983.

Haas graduated from high school in Mission Hills, California, in 1970. After high school, he attended California State University, Northridge, where he studied engineering and business. He graduated in 1975 with a Bachelor of Science Degree in accounting and finance.

In 1978, after working for three years as an industrial programmer, Haas founded Proturn Engineering, a small contract machine shop in Sun Valley, California. Haas worked side-by-side with his two employees at Proturn Engineering, machining parts for the electronics and aerospace industries. It was during that time Haas developed a fully-programmable 5C collet indexer to boost productivity in his own shop. The Haas 5C was the industry’s first device to automatically re-position parts accurately for machining by simply pressing a button, as opposed to having to reposition the material by hand – a cumbersome and time-consuming process.

The machine-tool industry received the economical and reliable Haas 5C Indexer with enthusiasm, and in 1983, Haas Automation, Inc., was born. The company started with three employees in a .465-square meter (5,000-square-foot) facility. During the next four years, Haas expanded his product line to include a wide selection of fully-programmable rotary tables, indexers and machine-tool accessories. Haas Automation quickly became the leader in fourth- and fifth-axis parts positioning.

In 1987, Haas took what he learned from the 5C Indexer and designed and developed his first vertical machining center (VMC) – the VF-1. The prototype was introduced to the manufacturing world in 1988 at the International Machine Tool Show (IMTS) in Chicago. Haas listed the machine at the unheard of price of $49,900. Industry experts were skeptical that an American company could manufacture and sell a machine tool for less than $50,000.

Haas Automation silenced the skeptics. The new product was a success. Today, virtually every manufacturer of vertical machining centers worldwide produce a similar machine in the $50,000 price range.

Over the next five years, Haas Automation began to grow. In 1992, Haas Automation moved to a larger facility in Chatsworth, California, to keep up with demand. In 1997, again seeking to keep up with the success of its growing product line and production demands, Haas Automation moved once more, to its current location in Oxnard, California, where all of its products are manufactured.

The 93.000 square-meter (1-million-square-foot) facility in Oxnard is one of the largest, most modern machine tool manufacturing operations in the United States. Haas Automation currently produces four major product lines: vertical machine centers (VMCs), horizontal machine centers (HMCs), computer numeric control (CNC) lathes and rotary tables.

Haas products are sold through a worldwide network of more than 170 Haas Factory Outlets in more than 80 countries providing the industry’s best support and service.

Although he founded Haas Automation and serves as its president, Haas’ primary role has always been heading up the engineering department. Ninety-five percent of all new design ideas originate through Haas himself. He sketches out his ideas and then turns them over to his engineers for refinement. After reviewing the engineers’ work, Haas makes further modifications, as required. One of Haas Automation’s strengths is its ability to take a new machine from initial concept, through design, and into production in just six to 12 months.

Haas’ desire to push innovation and tackle new challenges goes beyond his interest in machine tools.

In 2007, Haas built Windshear, one of the most advanced automotive wind tunnels in the world. It opened to its first customer, a Formula One team, in September 2008.

The facility’s centerpiece is a rolling road, which allows a full-size car to be restrained in place directly on top of a massive, treadmill-like stainless steel belt rotating at speeds up to 290 kph (180 mph). The rolling road accurately simulates the dynamics of a car on the racetrack, unlike traditional fixed-floor tunnels. The high-tech rolling road is able to accelerate from zero to 290 kph in less than one minute, with temperatures controlled within 1 degree Fahrenheit.

Windshear is the first wind tunnel of its kind in North America and only the third rolling-road wind tunnel of its scale in existence. Windshear is available for hire to all motorsports teams and auto manufacturers. NASCAR, INDYCAR, sports car and NHRA teams utilize Windshear, as does the United States Council for Automotive Research (USCAR), which has conducted tests on production cars at Windshear.

TEAM OWNER:

In addition to his professional accomplishments, Haas is passionate about auto racing. He has competed successfully in off-road racing and sponsored numerous race teams through the years in CART, INDYCAR, Formula One and NASCAR.

In 2002, Haas formed his own NASCAR Cup Series team, Haas CNC Racing. Originally headquartered in Concord, North Carolina, Haas CNC Racing began as a single-car team with chassis and technical support from Hendrick Motorsports. The team made its debut on Sept. 29, 2002 at Kansas Speedway in Kansas City with driver Jack Sprague.

The team raced only two more times in 2002, but by 2003, Haas CNC Racing was running the full NASCAR Cup Series schedule.

In 2006, Haas CNC Racing relocated to a new, state-of-the-art, 13,000-square-meter (140,000-square-foot) facility in Kannapolis, North Carolina, where it began fielding two, full-time NASCAR Cup Series teams.

On July 10, 2008, Haas announced that he had partnered with Stewart, then a two-time NASCAR Cup Series champion. The new operation, known as Stewart-Haas Racing, became official in January 2009. The team fielded two NASCAR Cup Series entries – one for Stewart and another for Ryan Newman.

Haas immediately began to see results of his new partnership. Stewart finished eighth in the season-opening Daytona 500 at Daytona (Fla.) International Speedway to score the first top-10 for SHR in just its first point-paying race. In late March, Stewart and Newman placed both cars among the top-10 in a race for the first time when Stewart finished third and Newman finished sixth at Martinsville (Va.) Speedway. In early May, SHR placed both cars among the top-five in a race for the first time when Stewart finished second and Newman finished fourth at Richmond (Va.) International Raceway.

Then on May 16, Stewart scored the first NASCAR Cup Series victory for SHR in the non-points All-Star Race at Charlotte (N.C.) Motor Speedway. The following week, on May 21, Newman scored the first NASCAR Cup Series pole for SHR in the Coca-Cola 600 at Charlotte.

SHR recorded its first point-paying NASCAR Cup Series victory when Stewart won the Pocono 500 at Pocono (Pa.) Raceway by 2.004 seconds over runner-up Carl Edwards. It marked the first time a driver/owner won a point-paying NASCAR Cup Series race since Ricky Rudd on Sept. 27, 1998 at Martinsville.

Stewart would go on to score SHR’s second NASCAR Cup Series win at Daytona in July and its third at Watkins Glen (N.Y.) International in August.

By Sept. 12, following the conclusion of the NASCAR Cup Series race at Richmond – the cutoff race for the NASCAR Playoffs – SHR was the only organization to place all of its teams in the playoffs.

With its inaugural season complete, SHR had placed both of its cars among the top-10 in the season-ending point standings. Stewart finished sixth in points while Newman finished ninth.

In 2010, SHR recorded three NASCAR Cup Series wins. Newman reached victory lane first when he won at Phoenix International Raceway in April. Stewart won twice – first at Atlanta Motor Speedway in September and again in October at Auto Club Speedway in Fontana, California. Stewart would go on to qualify for the playoffs and finish the season seventh in points. Newman finished 15th.

In August 2011, SHR announced it was adding a third team for INDYCAR star Danica Patrick, who would join the team for a limited NASCAR Cup Series schedule in 2012.

In September 2011, Stewart and Newman qualified for the playoffs. Stewart won five of the final 10 races, including the season finale at Homestead-Miami Speedway. With the victory, Stewart ended the season in a numerical tie with Carl Edwards, as each driver had 2,403 points. But Stewart won the championship by virtue of a tiebreaker, as his five wins on the season trumped Edwards’ lone victory. It was the closest NASCAR Cup Series championship in history. While it was Stewart’s third NASCAR Cup Series title, it was the first for SHR.

SHR picked up in 2012 just as it left off in 2011, as Stewart scored wins at Las Vegas Motor Speedway and Fontana. Newman also picked up a win early in the season at Martinsville. Stewart went on to win at Daytona in July and at Atlanta in August. In total, Stewart, Newman and NASCAR newcomer Patrick combined to collect five NASCAR Cup Series wins, 18 top-fives and 30 top-10s, along with a pole. Stewart qualified for the playoffs and finished ninth in points.

Patrick made the jump to a full-time NASCAR Cup Series schedule in 2013, joining SHR teammates Stewart and Newman, and she did it in a big way by winning the pole for the Daytona 500. Patrick’s pole win was the first NASCAR Cup Series pole ever won by a woman. Stewart would score the first win of the season for SHR at Dover (Del.) International Speedway in June and Newman would follow by winning the Brickyard 400 at Indianapolis Motor Speedway in July. Newman left the team at season’s end for another opportunity.

In 2014, SHR grew again with addition of a fourth car for Kurt Busch, sponsored by Haas Automation. Also joining SHR was Kevin Harvick. The duo combined to win six races in 2014, with both drivers qualifying for the playoffs. Busch won at Martinsville in April while Harvick took victories at Phoenix in March, Darlington (S.C.) Raceway in April and Charlotte in October before scoring back-to-back wins in November at Phoenix and Homestead to secure the 2014 NASCAR Cup Series championship. It was the second NASCAR Cup Series title for SHR and it came only two years after Stewart won the team’s first championship.

SHR recorded five wins in 2015. Harvick took three victories – Las Vegas in March, Phoenix in March and Dover in October. Busch won at Richmond in April and at Michigan International Speedway in Brooklyn in June. Both drivers qualified for the playoffs, with Harvick finishing second in the championship by a single point.

Three of SHR’s four drivers made the playoffs in 2016, as Harvick, Busch and Stewart all scored victories. Harvick won four races – Phoenix in March, Bristol (Tenn.) Motor Speedway in August, New Hampshire Motor Speedway in Loudon in September and Kansas Speedway in Kansas City in October – while Busch won at Pocono in early June and Stewart won at Sonoma (Calif.) Raceway in late June. It was another successful NASCAR season, but SHR opted not to rest on its laurels. It announced that it would switch manufacturers to Ford beginning with the 2017 season.

Its inaugural year with Ford started off with a bang, as Busch won the season-opening Daytona 500. Harvick also joined Busch in the winner’s circle, taking victories at Sonoma in June and Texas Motor Speedway in Fort Worth in November. Both drivers represented SHR in the playoffs, with Harvick advancing all the way to the Championship 4 for the third time in the last four years.

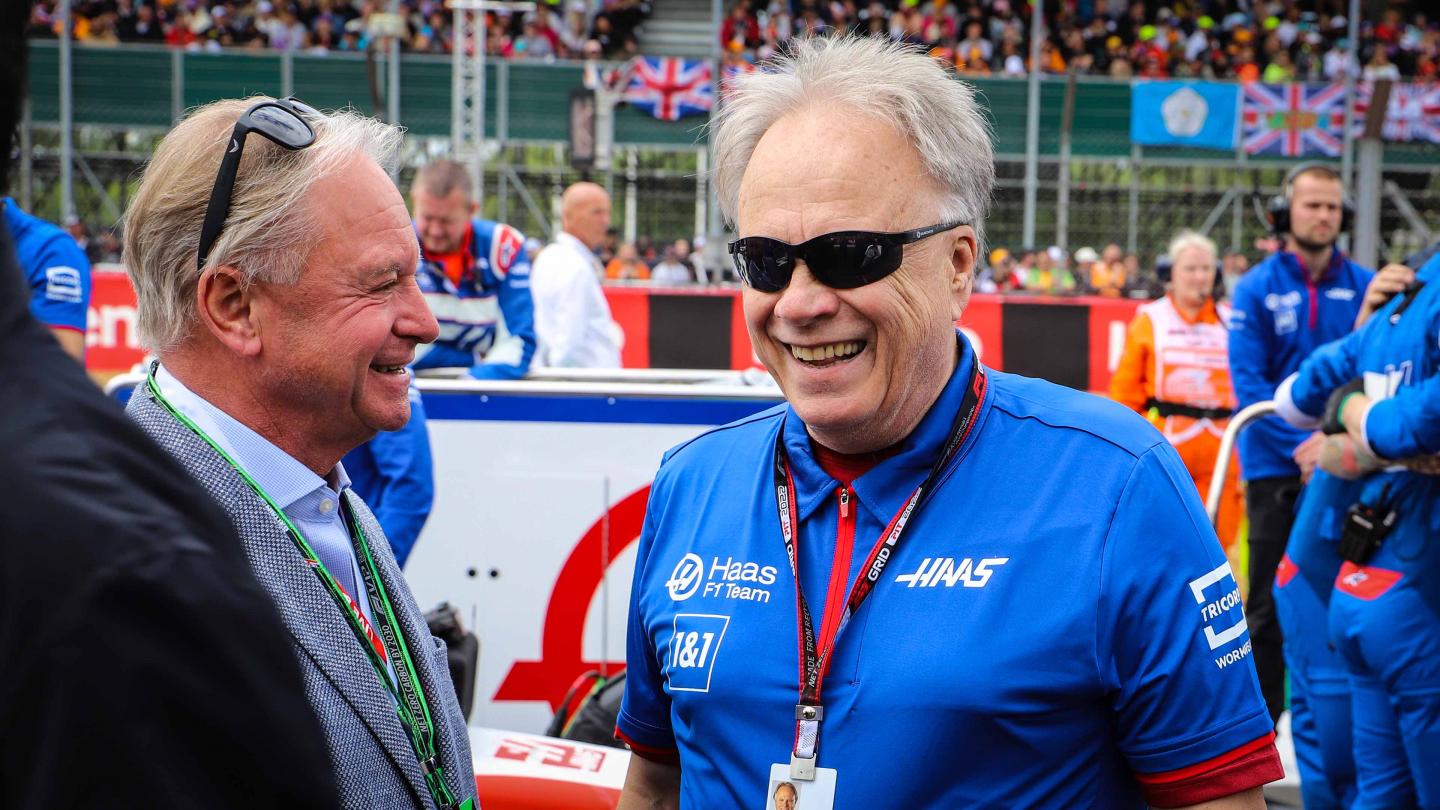

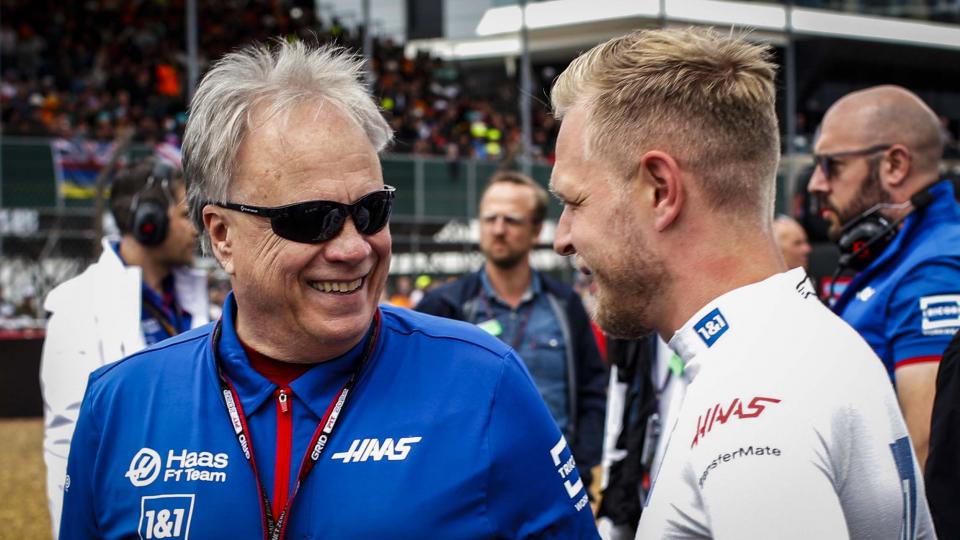

NASCAR isn’t the only growth area for Haas’ motorsports ambitions. On April 11, 2014, Haas was granted a license by the Federation Internationale de l’Automobile (FIA) to join the starting grid of the FIA Formula One World Championship in 2016. In its inaugural season, Haas F1 Team finished eighth in the constructor standings with a total of 29 points, the most of any new team in this millennium. The outfit followed up that run with an even stronger sophomore campaign, earning 47 points and maintaining its eighth-place standing.

The first American Formula One team since 1986 operates out of an 11,600-square-meter (125,000-square-foot) facility adjacent to Haas’ NASCAR Cup Series team in Kannapolis, North Carolina. Haas F1 Team also has a European base in Banbury, Oxfordshire, U.K., allowing for easier and quicker access to the team’s overseas suppliers and streamlined logistics for travel to European Formula One venues.

PHILANTHROPIST:

Haas established the non-profit Gene Haas Foundation in 1999 to help fund community humanitarian causes as an official commitment to corporate and social responsibility. The Foundation supports local, state and international communities through grants to charities, non-profit organizations and other philanthropic foundations. Since its inception, the Gene Haas Foundation has awarded nearly of $25 million to almost 1,000 organizations such as the YMCA, United Way, Salvation Army, Boys and Girls Clubs of America, Food Share, National Breast Cancer Foundation, American Red Cross and many others.

Haas is also a firm believer in education. The Gene Haas Foundation supports a variety of programs, particularly in the technical and engineering fields at schools, colleges and universities worldwide, including Ranken Technical College, Rensselaer Polytechnic Institute, and his alma mater, California State University-Northridge. Additionally, the Gene Haas Foundation has provided grants and scholarships for the American Association of University Women, the NAACP, the Society of Manufacturing Engineers Education Foundation and numerous others.

To augment the Foundation’s work, Haas and Haas Automation established a worldwide network of Haas Technical Education Centers (HTECs), which play a vital role in many local training centers, community colleges and universities. HTECS provide an environment that allows students to take theory out of the classroom and apply it within modern manufacturing. Students learn machining and metalworking skills through a hands-on approach, using the types of Haas CNC machine tools they will encounter upon entering the workforce.